FR-4 Material Factory

Strength Enterprise of Composites Solutions

Specification Overview

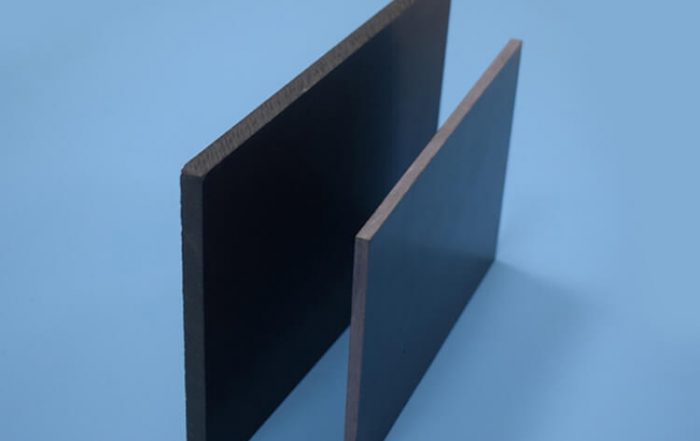

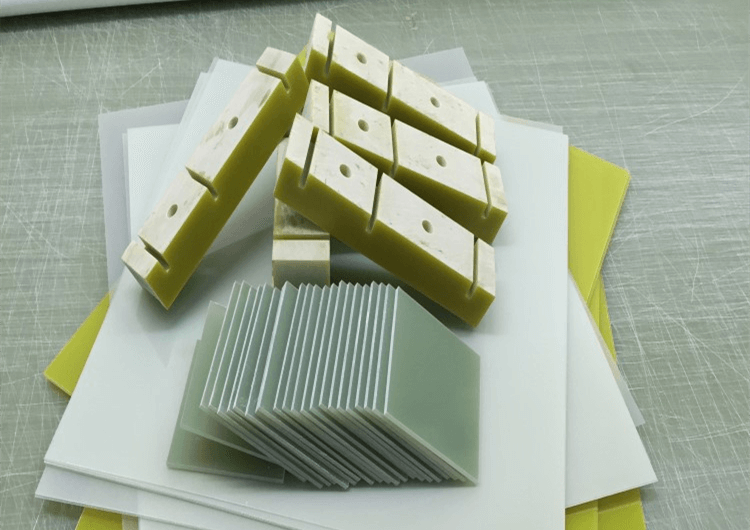

Name: FR4 Epoxy Fiberglass Laminate Sheet

Base Material: Epoxy resin + Fiber glass

Color: Green\yellow\red\black\white,etc

(Color can be customized according to customer requirements)

Thickness: 0.1mm – 300mm ( More than 300mm can be produced according to product requirements)

Dimensions: Regular size are 1020x1220mm,1020x2040mm,1220x2440mm; Special size, we can produce and cut according to customer’s requirements.

Density: 1.97g/cm3 – 2.2 g/cm3

OEM: Accepted

More Products Information

Navigating the World of Epoxy Resin: Where to Buy and What to Consider

Discover the best places to purchase epoxy resin, from online retailers to direct manufacturers, along with key considerations for ensuring quality and value.

Understanding Epoxy Resin Cost Dynamics in India: A Global Manufacturer’s Perspective

Explore how our strategic sourcing, efficient production, and optimized logistics enable us to offer competitively priced epoxy resin sheets in India.

Deciphering the FR4 PCB Datasheet: Key Performance Parameters to Consider

Selecting the right FR4 for PCB applications involves understanding the material's datasheet and considering how each specification will impact the final product's performance.