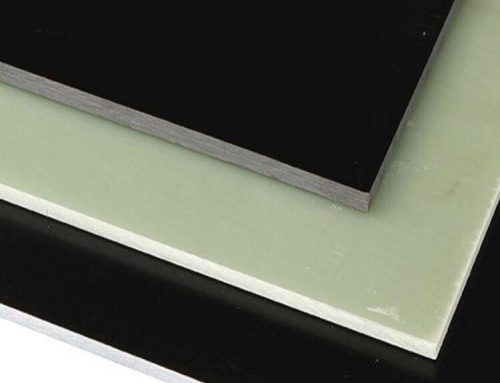

FR4, a grade designation for flame retardant glass-reinforced epoxy laminate sheets, is the material of choice for the majority of Printed Circuit Boards (PCBs). The material’s unique combination of superior electrical insulation, stability under variable temperature conditions, and excellent mechanical strength make it ideally suited for this application. This article will delve into the FR4 datasheet, highlighting key performance parameters relevant for its application in the PCB industry.

Firstly, it’s crucial to understand the constituents of an FR4 datasheet. It typically includes technical specifications such as thickness, sheet size, color, flammability rating, water absorption rate, dielectric constant, dielectric strength, and glass transition temperature (Tg), among others. Each of these parameters can significantly impact the performance of FR4 in PCB applications.

1.Thickness:

The thickness of the FR4 sheet is a vital factor as it dictates the board’s mechanical strength and weight. Commonly, PCBs utilize FR4 sheets with thicknesses ranging from 0.2mm to 3.2mm.

2.Flammability Rating:

FR4 is flame-retardant, as indicated by its ‘FR’ prefix. The flammability rating is typically UL94-V0, the highest rating, indicating that the material stops burning within 10 seconds after being set alight.

3.Water Absorption:

This parameter is a measure of how much moisture the FR4 material can absorb. A lower water absorption rate is preferable for PCB applications as moisture can affect the board’s electrical properties.

4.Dielectric Constant (Dk) and Dielectric Strength:

The Dk is a measure of the material’s ability to store electrical energy. A lower Dk results in better signal transmission. The dielectric strength indicates how much electric field the material can withstand without breakdown, a critical aspect for high-voltage applications.

5.Glass Transition Temperature (Tg):

Tg is the temperature at which the FR4 material transitions from a glassy, rigid state to a softer, more pliable state. A higher Tg indicates better performance at elevated temperatures. Typical values for FR4 range between 130°C to 180°C. High Tg FR4 is often used in applications with high ambient operating temperatures.

Selecting the right FR4 for PCB applications involves understanding the material’s datasheet and considering how each specification will impact the final product’s performance.

Always remember that the best material will depend on the specific requirements of your PCB design and its intended application.

A thorough understanding of the FR4 datasheet will ensure you make an informed choice and achieve optimal PCB performance.