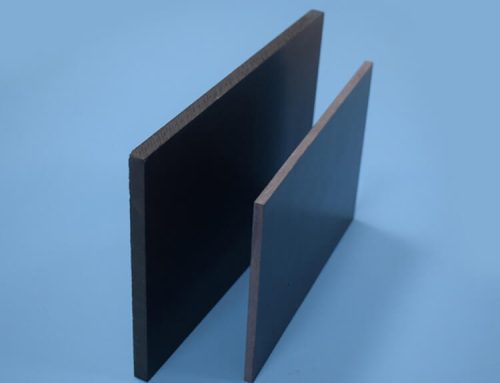

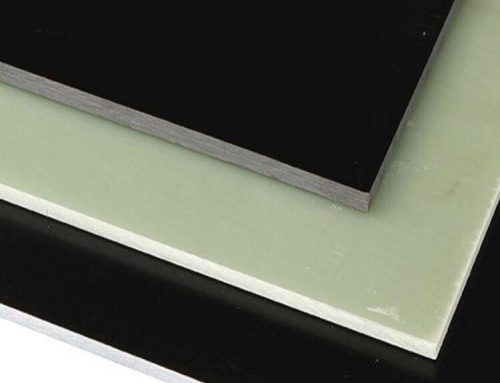

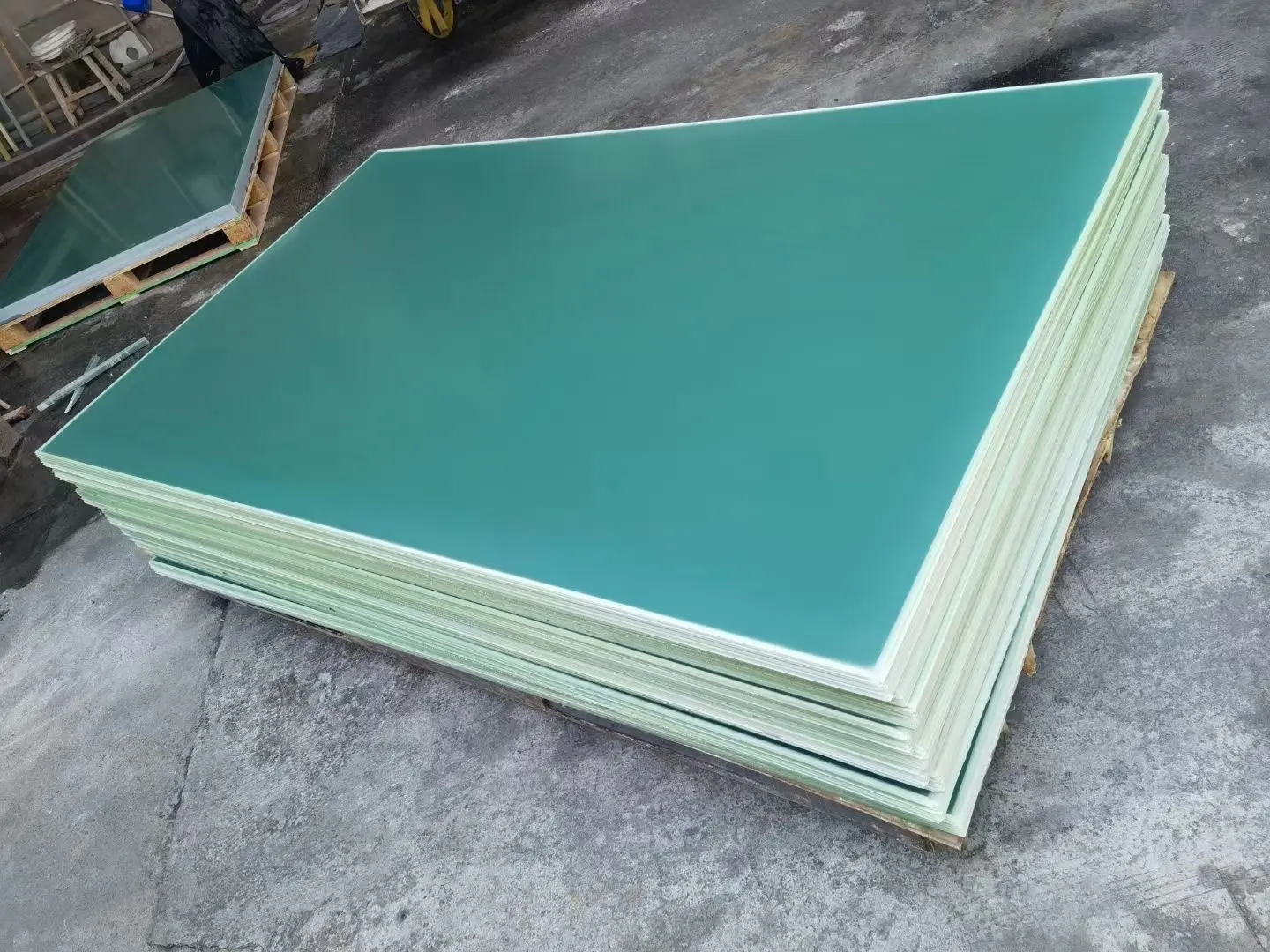

G10 FR4 Glass Epoxy, a composite material known for its durability, mechanical strength, and excellent insulating properties, has found its place in a vast array of applications. This sheet material, crafted from woven glass fabric and epoxy resin, holds a unique standing in many industries.

For industrial insulation, G10 FR4 Glass Epoxy is the material of choice. Its high dielectric strength, low electrical conductivity, and resistance to high voltage make it an excellent insulator. It’s frequently used in electrical equipment such as transformers, circuit boards, and electric motor components, providing a safe barrier between electrical conductors.

Another significant application of G10 FR4 lies in composite materials. Its superior mechanical properties, including high tensile strength, stiffness, and impact resistance, make it an ideal reinforcement material in composites. When combined with other materials, the G10 FR4 significantly enhances the composite’s overall structural integrity and durability.

The aerospace and military industries also benefit from the unique properties of G10 FR4 Glass Epoxy. Here, the material’s high strength-to-weight ratio and dimensional stability under extreme conditions become crucial. It’s used in the manufacture of components that must withstand severe mechanical stresses, extreme temperatures, and resist corrosive chemicals. The material’s light weight is especially beneficial in aerospace applications, where reducing weight is always a priority.

The mechanical robustness of G10 FR4 Glass Epoxy also makes it a favorite in the construction and automotive industries. In construction, the material serves as high-strength, weather-resistant panels for cladding or roofing. In automotive applications, G10 FR4 is used in parts that require strength and heat resistance, such as under-the-hood components.

Additionally, the G10 FR4 Glass Epoxy is available in various forms, thicknesses, and sizes to cater to different needs. This versatility allows the material to be tailored to specific applications, ensuring optimal performance.

Manufacturers of G10 FR4 Glass Epoxy adhere to strict quality control measures. Each sheet undergoes rigorous testing to confirm it meets the required standards for strength, electrical insulation, and heat resistance. This commitment to quality ensures that the material reliably performs in whatever application it’s used.