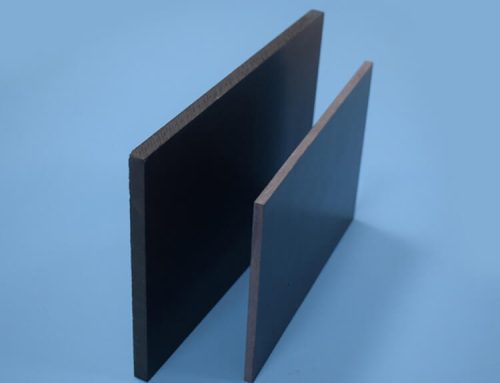

FR4 glass epoxy, also known as FR4 laminate, is a type of composite material that is commonly used in the manufacturing of printed circuit boards (PCBs) due to its excellent electrical insulation properties and high mechanical strength. If you’re in need of FR4 glass epoxy, it’s important to understand its properties, applications, and manufacturing process.

Properties of FR4 Glass Epoxy

FR4 glass epoxy is made by impregnating a glass fiber cloth with an epoxy resin and then compressing it under high pressure and temperature. The resulting material has several properties that make it ideal for PCB manufacturing, including:

High electrical insulation: FR4 glass epoxy has a high dielectric strength and low dissipation factor, making it an excellent electrical insulator.

Mechanical strength: FR4 glass epoxy has high mechanical strength, including tensile strength, flexural strength, and impact strength.

Thermal resistance: FR4 glass epoxy has good thermal resistance, making it suitable for applications where the PCB is exposed to high temperatures.

Applications of FR4 Glass Epoxy

FR4 glass epoxy is primarily used in the manufacturing of printed circuit boards due to its electrical insulation properties and mechanical strength. It is commonly used in a wide range of applications, including:

Consumer electronics: FR4 glass epoxy is widely used in consumer electronics such as smartphones, tablets, and computers.

Industrial electronics: FR4 glass epoxy is also used in industrial electronics, including control systems, power supplies, and instrumentation.

Aerospace and defense: Due to its high mechanical strength and thermal resistance, FR4 glass epoxy is used in aerospace and defense applications, including avionics and missile guidance systems.

Manufacturing Process of FR4 Glass Epoxy

The manufacturing process of FR4 glass epoxy typically involves the following steps:

Glass fiber cloth impregnation: The glass fiber cloth is impregnated with an epoxy resin.

Prepreg formation: The impregnated cloth is then partially cured to form a prepreg.

Layup: The prepreg is then laid up into the desired configuration.

Pressing: The layup is then compressed under high pressure and temperature to form the final FR4 glass epoxy laminate.

Choosing the Right FR4 Glass Epoxy Supplier

When choosing an FR4 glass epoxy supplier, it’s important to consider several factors, including:

Quality: The quality of the FR4 glass epoxy laminate is crucial to ensuring its performance in your application. Be sure to choose a supplier that uses high-quality materials and manufacturing processes.

Customization: Depending on your needs, you may require customized FR4 glass epoxy laminates in terms of size, thickness, or other properties. Look for a supplier that can provide customized solutions to meet your specific needs.

Pricing: While pricing is an important consideration, it’s important not to sacrifice quality for cost. Look for a supplier that offers competitive pricing without compromising on quality.

Customer Service: Working with a supplier that provides excellent customer service can make all the difference in ensuring a smooth and successful ordering process. Look for a supplier that is responsive and easy to work with.

FR4 glass epoxy is a versatile and reliable composite material that is commonly used in the manufacturing of printed circuit boards. By understanding its properties, applications, and manufacturing process, you can make an informed decision when choosing an FR4 glass epoxy supplier that meets your specific needs. With the right supplier, you can be confident in the reliability and performance of your FR4 glass epoxy laminates.